PRIS-MAG occupies a surface of 50.000 m², 11.000 of them covered for production.Company Profile

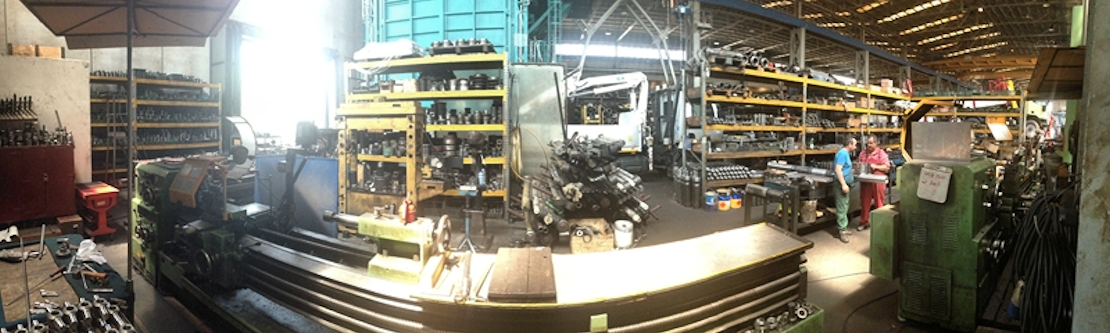

Inside the workshop of Cambiago (Milan), there are the departments for working and preparing every mechanical component which is needed for a special and specific equipment: press-and cut- machines, benders, welders and every type of machines necessary for our work.

We also dispose of different lathe machines, in this way we can build and repair cylinders of different measures.

A shot-blasting system and 3 painting cabs close the production cycle of our bodyworks. Everything is build inside our workshop.

A well refurnished depot : we must assist our customers every day in their unexpected situations, then some sudden cases of after-sales assistance may occur every day and we want to be ready in every situation.

The technical department is in charge of elaborating calculations, mechanical projects, documents for final type approvals, Ce certification.

Our group is composed by very well-trained co-workers, skilful people with long experience in this sector.

We guarantee an efficient after-sales service : continuing during every month of the year.

Pris-mag can project and produce every kind of equipment according to the customers’ needs, starting from the whole producing process of each single element up to the certification and authorisation of the product.

We build using high quality certified materials: special steel, high level stress property materials, iron sheets coming from German and Swedish steelworks.

We pay particular attention to the details of our metal carpentry trying to follow some special requests of our customers.

Cooperation with trucks- and cranes-producer Companies, partnership with the major Companies for hydraulic, pneumatic and electrical components, give us the chance to put on the market an extremely technical performing, safe and efficient equipment.